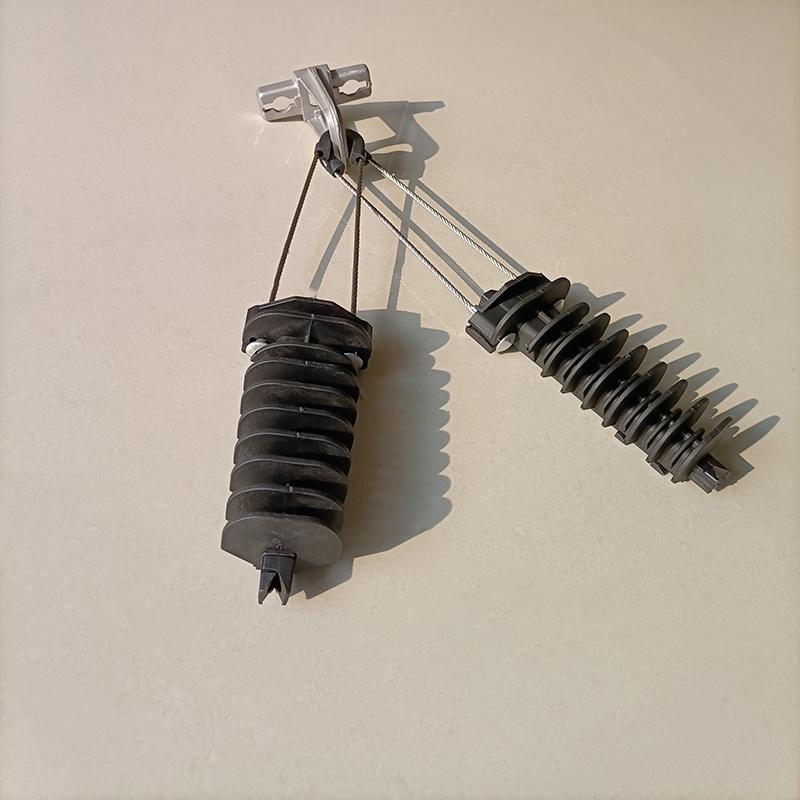

OPGW Optical Cable Tension Fitting StringFeatures:a. Even stress distribution, no stress concentration point, can well protect the optical cable.b. Under the premise of not exceeding the lateral compression strength of the optical cable, it has a greater grip on the optical cable and can withstand greater tension.c. The grip strength of the optical cable is not less than: 95% of the ultimate tensile strength (UTS) of the optical cable, which is completely suitable for the needs of optical cable erection. Schematic diagram of product composition:Technical specification sheet

Contact Now

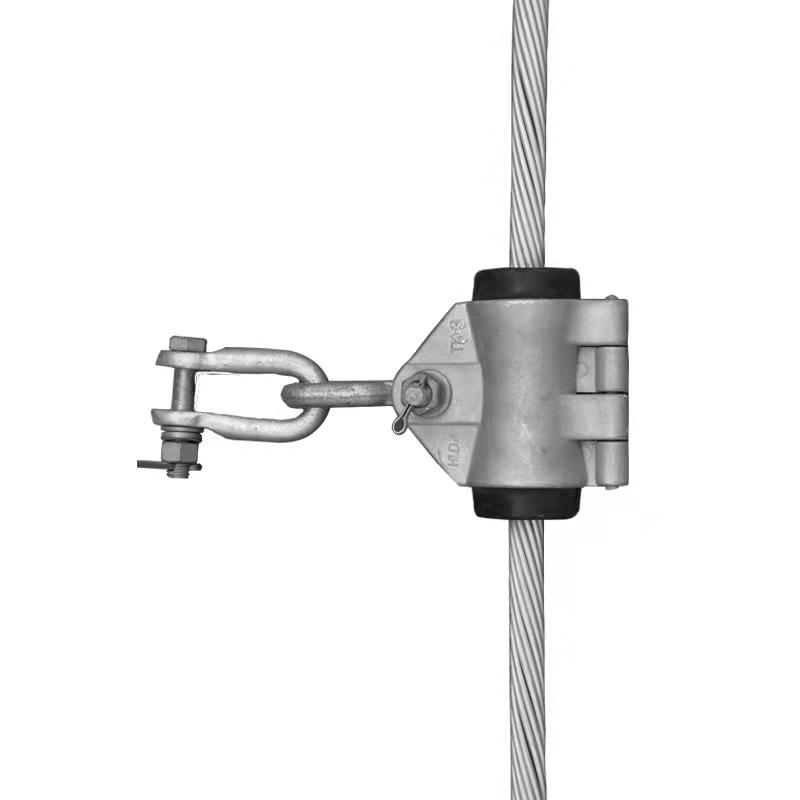

The grounding clamp is mainly used for the grounding of the OPGW optical cable to provide a path for short-circuit current. The grounding clamp consists of a grounding wire, a set of aluminum alloy parallel groove clamps (connecting OPGW optical cable and grounding wire) and a terminal (connecting to the iron tower). Usually, one terminal tower and linear tower are equipped, and two connecting towers are equipped.

Contact Now

The second damper can be used for OPGW tension tower vibration dampers if necessary. Tension assembly is used for OPGW cable route's fixing and anchor shackling. Usually be installed on the terminal tower, tight tension tower and intersection angle tower.OPGW tension tower vibration dampers installation image:

Contact Now

The OPGW grounding clamp consists of a section of aluminum alloy wire, an aluminum alloy clamp (connected to the OPGW optical cable), and all-aluminum terminal blocks (connected to the main material of the iron tower).

Contact Now

ADSS optical cable rubber rod down-lead clamp is made of corrosion-resistant, weather-resistant EPDM rubber. It is used for fixing ADSS on the pole tower, suitable for different cable diameters, convenient and reliable installation, and wide adjustable range.1.Function: Fix the optical cable leading up or down on the pole tower to prevent it from shaking and avoid the optical cable from wearing. 2.Condition: The fiber optic cable line and the continuous poles on the first and end poles. 3.Method: usually install one every 1.5 meters.Technical specification table:

Contact Now

Dead end clamp is made of plastic body with very high mechanical and climatic resistance. A stainless steel flexible cord equipped with movable insulating saddle and two sleeves compressed on the ends to prevent detachment from the clamp body.An inner sheath consisting of two insulating plastic wedges for clamping of the neutral carrier without damaging the cable insulation.

Contact Now

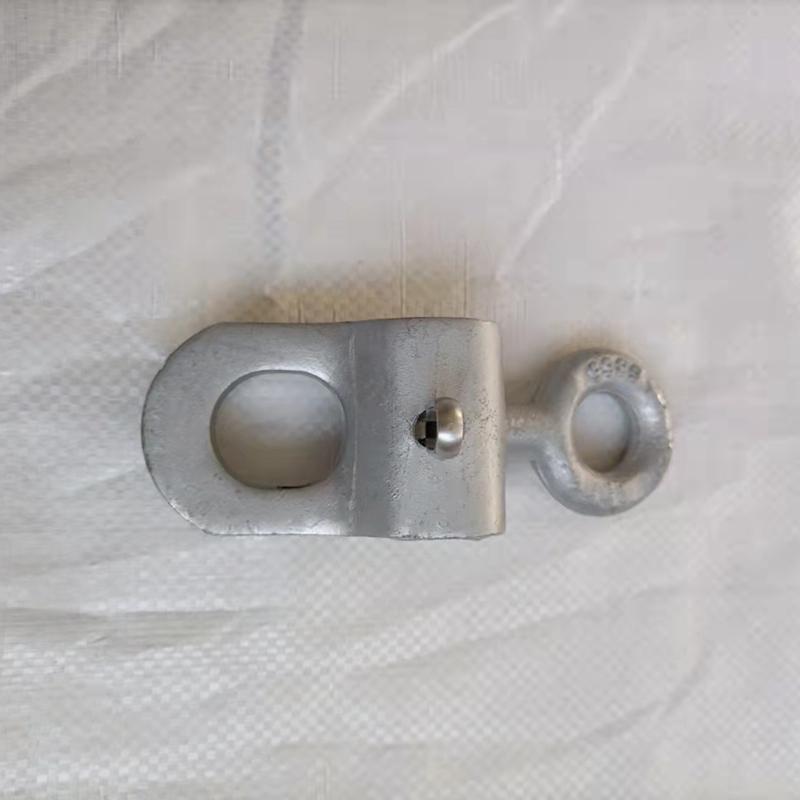

Retention Clamp for ADSS cable single extension 50M span cable diameter 9.0-9.5mmTension splint for ADSS tower is made of forged hot dip galvanized steel.use: for installation and maintenance of aerial construction fiber optic networks.Technical Characteristics1. Fitting material: Steel under ASTM A-362. Minimum yield strength: 250Mpa.3. Minimum tensile strength: 400Mpa4. Post fastening method: By 3/4” steel tape.5. Solder points with smooth and uniform finishes6. Hot dip galvanized according to ASTM A 123 Dimensions1. Fitting base dimensions:

Contact Now

Suspension string fittings include U-shaped screws, suspension clamps, pre-twisted wire protection lines, grounding drain wires and necessary connection fittings. The mechanical strength of the hanging string connection fittings is 70kN. The suspension clamp is a pre-twisted wire type, and the clamp body is made of aluminum alloy. The clamp body should be equipped with an EPDM rubber cushioning elastic pad. The allowable value of the drape angle at the outlet of the OPGW single drape clamp is not less than 15 degrees.

Contact Now

Applications 1.Tensile clamps for OPGW optical cables are mainly used to connect optical cables with a breaking strength of 160kN and below to tensile poles, corner poles and terminal poles. The complete set of OPGW optical cable strain clamp includes outer pre-twisted wires, inner pre-twisted wires, supporting connectors and grounding wires.

Contact Now

The wire clamp is composed of a rubber clamp block, a pre-twisted wire and a cast aluminum casing. 1. Enhance the rigidity of the cable hanging point and increase the radius of curvature. The single-line clamp can meet the 30° steering angle, and the double-line clamp can meet the 60° steering angle. 2. It can be ensured that the cable is not subject to large bending stress near the outlet of the wire clamp, so as to avoid local mechanical damage causing strand break or wire breakage.

Contact Now

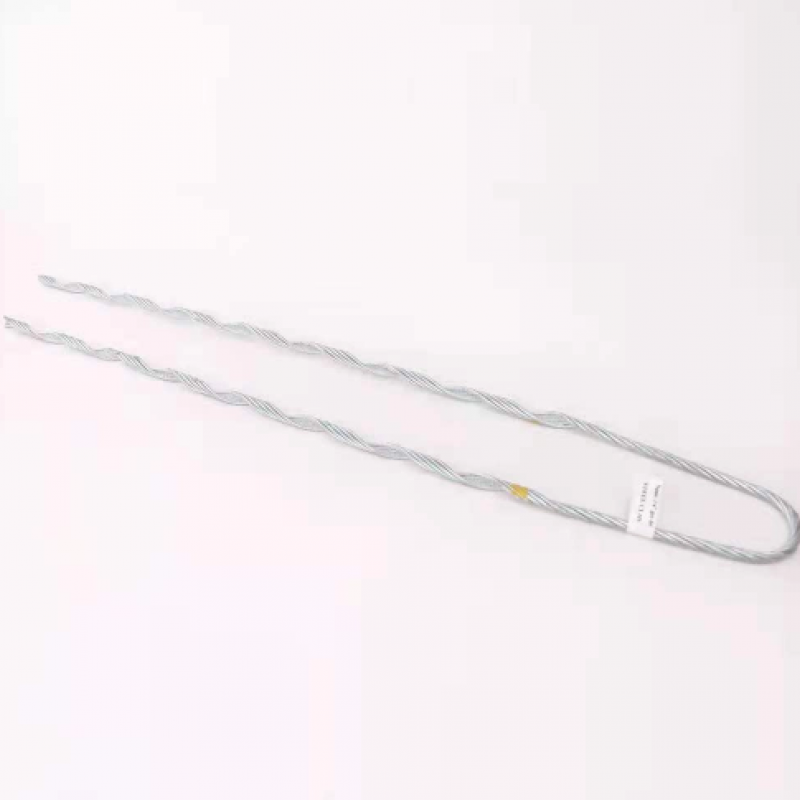

Product advantages: 1. There is a large contact area between the clamp and the pull wire, the stress distribution is even, there is no stress concentration point, and the achievable grip strength is not less than 95% of the stranded wire Calculate the breaking force. 2. The dead end preformed guy grip is made of the same material as the pull wire, which has good corrosion resistance. 3. The dead end preformed guy grip is simple to install, without any special tools, and can be done independently by one person.

Contact Now

The surplus cable rack is used to suspend and fix the surplus OPGW optical cable and ADSS optical cable on the tower in the overhead line for maintenance and inspection. 1.The remaining cable rack for poles is fixed on the poles by two sets of steel band hoops 2. The remaining cable frame for the tower is fixed on the iron tower angle steel by two sets of right-angle splints.Purpose: It is used to place the surplus optical cable when the optical cable is connected.

Contact Now

Preformed inner protection line rods:The material is aluminum-clad steel wire, which is the same material as all the aluminum-clad steel wires of OPPC cable. The inner wall of the protector rods is glued with a layer of gold steel sand through a high-strength polymer water-soluble environmentally friendly adhesive to increase the friction with the optical cable. The rods is preformed into four sub-bundles during production, which is convenient for quick installation.

Contact Now

ADSS terminating helix dead end is made of aluminum-clad steel wire, and the pre-twisted wire is preformed into a bundle during processing, and a firm layer of emery is glued to the inner wall to increase the grip of the tension clamp under the condition of reducing the side pressure on the optical cable.

Contact Now

ADSS optical cable tower with down-lead clamp, optical cable clamp, fixed optical cable clamp.The lead-down clamp is used to lead down the optical cable and fix the optical cable when it is jumpered, which improves the mechanical performance of the clamp. It is mainly used for the communication line of the newly built overhead high-voltage power transmission system of 35kv and above. The stainless steel tube and cable core stranding design is reasonable, and the optical fiber is redundant.

Contact Now

Suspension set for ADSS features: 1.This product has uniform stress distribution and no stress concentration points, which can enhance the 2. Rigidity of the cable installation point without additional damage to the optical cable; The tangent clamp has a high dynamic stress bearing capacity, which can effectively lift and fix the line; 3.

Contact Now

The U shackle is made of forged steel, has a wide range of uses.

Contact Now

ADSS optical cable suspension clamps are divided into several types according to the size of the line span, such as single-layer pre-twisted wire tangent clamps, single suspension clamps and double suspension clamps. The tangent clamp for ADSS optical cable is mainly used for the cable erection of 100m span, and the single-layer pre-twisted wire suspension clamp is mainly used for the erection of optical cable within the span of 100m-200m.Features: a. The suspension clamp has a larger contact area with the ADSS/OPGW optical cable, the stress is evenly distributed, and there is n

Contact Now

Dimensions:Height: 460±5mm.Min Dry Aring Distance:235mm. Min Creepage Distance:675mmDiameter Of The Rod:Φ17mm.Coupling Dimensions: Single Ear/ Binaural.Number Of Sheds: 6. Raw Materials:1. End-Fitting:1.1Material: Socket: Cast Iron Or Cast Steel, Hot Dip Galvanized. Ball: Forged Steel, Hot Dip Galvanized.1.2 Minimum Thickness Of The Galvanization:86um.2. Core:2.1 Material: Epoxy& Glass Fiber, Acid-Resistant Type.2.2 Diamter:Φ17mm.3.

Contact Now

Helical tension set ADSS long span with D shackle, Thimble clevis, helical dead end, protector rods. A dead-end is installed at each end of the cable length to attach to the structures. Two dead ends are used at angle changes of 30 degree or greater, either horizontal or vertical.

Contact Now

Features: 1. The application force has no concentrated point, the stress is uniform, and it has a good protective effect on the optical cable. 2. Under the premise of not exceeding the lateral compression strength of the optical cable, it has a greater grip on the optical cable and can withstand greater tension.

Contact Now

Preformed dead end, Clamp-wedge Anchor (stainless steel), 5.5*8.5+-0.2mm for Flat mini FTTH cable outdoor middle size. Our SS wedge anchor clamp with the advantages below:1.Reduce cable maintenance expenses, avoid frequent repairs, save operating costs, and users get a better experience. 2.The FTTH technology has been widely used, the construction speed is also very fast, and the technical risk is low. 3. It provides a stable and reliable guarantee for fiber to the home, and the efficiency of network usage is improved.Dimension: 210×15mmDrawing:Installation image:

Contact Now

Features: 1. It has all the functions of a single suspension clamp.2.

Contact Now

Transmission line fitting socket tongue is suitable for connecting suspension insulator strings between overhead power lines and substations. In the transmission line, the bowl head hanging plate plays the role of hanging the insulator string and the suspension clamp, and bears greater working stress.Features: 1. Cast, hot-dip galvanized.2. Connection mark 16; 20; 24.3. Equipped with W pins, the pins are stainless steel or bronze.

Contact Now